Checking Your Boiler Water Pressure

Loss of water pressure is common issues that arise with boilers. Low pressure is relatively easy to diagnose, as most boilers have a built-in pressure gauge. It’s possible to correct water pressure yourself.

WHAT YOU WILL NEED

- Boiler instruction manual

SAFETY TIPS

Always ensure that the central heating is turned off and that you allow sufficient time for it to cool down.

If you do not know what you are turning under your boiler - then do not turn it!

Water pressure is essential to the efficient running of your boiler system. Pressure in most modern combination boilers is maintained by cold water flowing from the water mains cold supply, through a filling loop. Some boilers have it built into the boiler (check your manual).

What causes a drop in pressure?

A number of things can cause pressure to drop. One may be that there is a leak somewhere in your house. Maybe, if you bled your radiators recently, it may be that pressure was lost during the bleeding. However, you may not be able to tell that you have a problem until you check the pressure gauge. A water leak, for instance, may be tiny and go unnoticed at first, only to develop into a bigger problem later.

Checking your pressure gauge

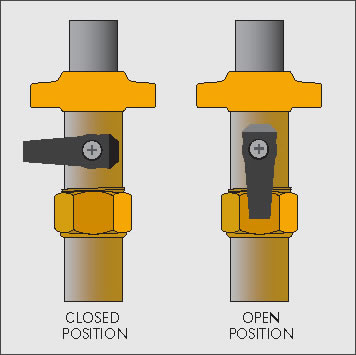

Check the water pressure gauge or indicator, which is typically on the front of your boiler. For most boilers, this should be set to around the 1 bar (1)

If you have noticed repeated drops in your boiler pressure, then give Trevolution a call. You may have a problem with the boiler and we would be more than happy to help fix it.

Before re-pressurising your heating system please ensure that the heating system has cooled down.

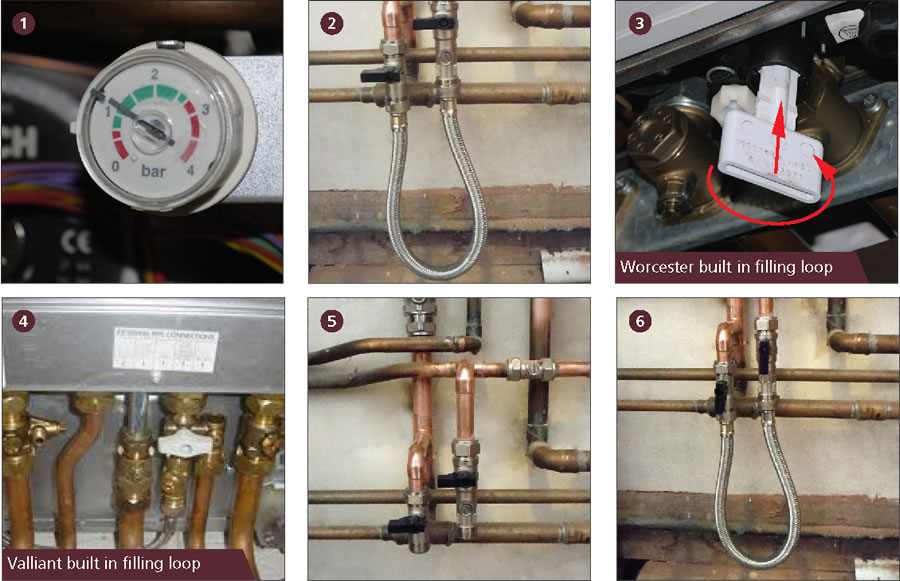

If you have an external filling loop it will be silver coloured and braided (2). It should be located close to the boiler but is often found under the sink if the boiler is in the kitchen. Some boilers have a built in filling loop (3 and 4) and you would have to read you boiler intruction manual for this. You may need the attach the filling loop, as this should be disconnected when not in use to prevent back feeding (5). The braided hose will have a valve fitted on either one or both ends. Turn the tap so they are in line with the pipe (6) and watch the pressure gauge move up to around 1 to 1.5 bar, then turn both taps off and remove the filling loop (5). The boiler should now work, but some boilers may need to be reset. First check with you boiler manual. If you do have a built in filling loop you would fill it the same way. You would just need to locate the taps used to fill the system on your boiler.